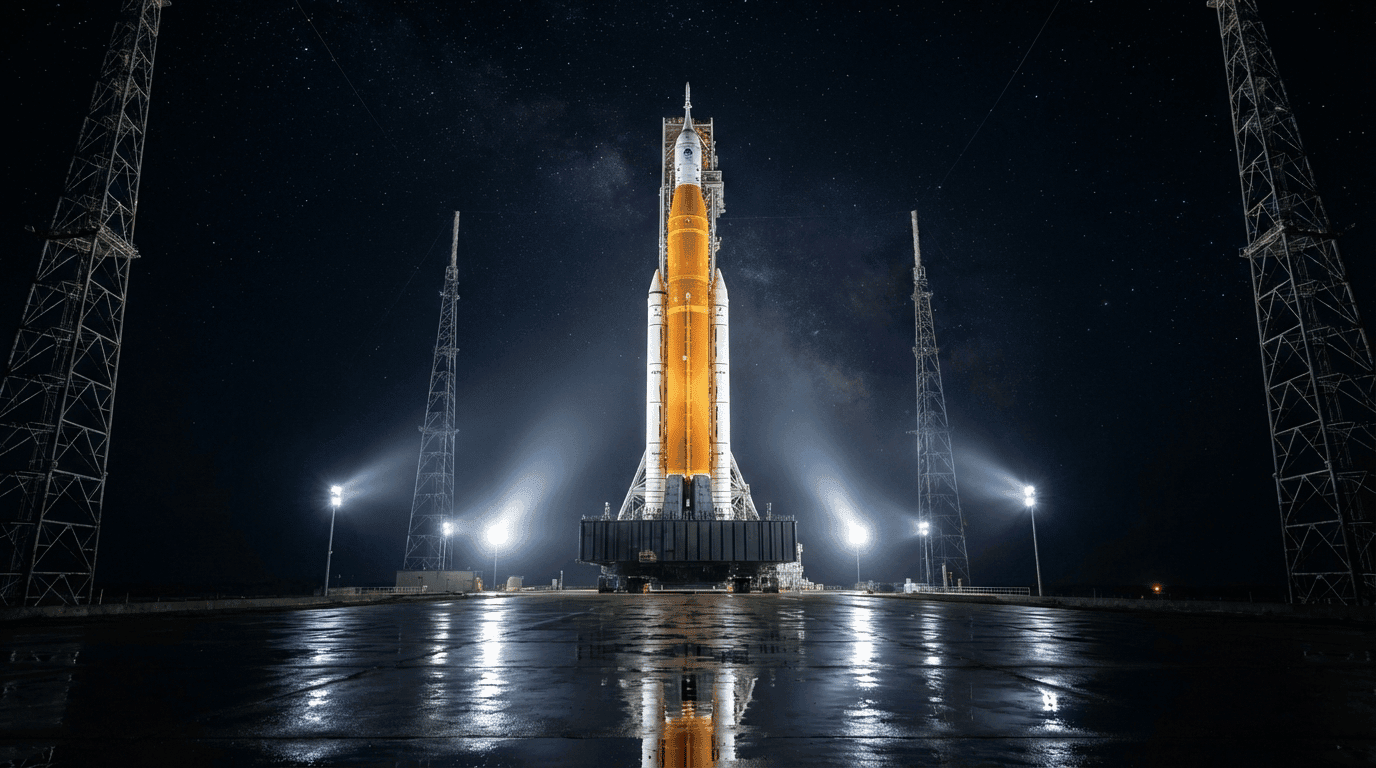

Everyone remembers the splashdown. The pristine parachutes, the cheering control room, the perfect orbital mechanics of Artemis I. It looked flawless. But if you’ve been in this industry as long as I have, you know that “flawless” is usually just a polite cover for “we got lucky.”

The reality? Artemis I was a stress test that nearly broke the machine.

When you peel back the PR gloss, the mission didn’t just validate the hardware; it exposed cracks in the armor that kept engineers awake at night. We aren’t talking about minor glitches. We’re talking about heat shields shattering and launch pads getting ripped apart by acoustic violence. NASA is now in a flat-out sprint to patch these holes before they strap four human beings to the top of that Roman candle.

Here are the five hurdles that scare me the most.

1. The Multi-Billion Dollar Ski Resort

I’ve seen a lot of contingency plans, but the Emergency Egress System (EES) at Pad 39B still makes me chuckle. It’s low-tech. It’s ugly. And it’s absolutely vital.

Imagine this: The countdown clock halts. Something is leaking, burning, or about to blow. The crew has seconds to get out. They don’t take an elevator. They jump into what are essentially industrial ski gondolas.

These baskets slide down a 1,335-foot cable, dropping from the 274-foot level of the tower to the ground, where an armored vehicle is waiting to drag them to a triage bunker. It’s a terrifying ride. And here’s the kicker—we’ve never used it. Not once. In the entire history of the American space program, no crew has ever had to pull that rip cord during a live countdown.

NASA says it’s “unlikely” they’ll need it. Sure. But I’ve learned that in aerospace, “unlikely” is just code for “it hasn’t happened yet.” The fact that they are meticulously testing these baskets tells you everything you need to know. They aren’t taking chances.

2. The Rocket Ate the Pad

We knew the Space Launch System (SLS) was a beast. But nobody expected it to be a cannibal.

When Artemis I lifted off, the sheer acoustic energy—the noise, the pressure waves—didn’t just rattle the windows. It tore the Mobile Launcher apart. Elevator doors were blown off their hinges. Sixty electrical panels were bent and forced open by vibrations hitting 6 to 8 Hz. Pneumatic lines rusted almost instantly from the acidic exhaust of the solid boosters.

NASA budgeted $5 million for repairs. The bill is currently north of $26 million.

That’s a staggering miss. It suggests our models for acoustic loads were wrong. Way wrong. And that’s the scary part. If we underestimated the violence of the launch environment for the tower, did we underestimate it for the crew? It’s like building a cage for a lion and realizing too late that the lion can chew through steel.

3. The Heat Shield Didn’t Just Melt—It Shattered

This is the big one. The showstopper.

Orion’s heat shield is designed to “ablate.” That’s a fancy engineering term for “burn away slowly to carry off heat.” It’s like a bar of soap wearing down in the shower. Predictable. Safe.

But that’s not what happened.

Instead of eroding smoothly, the Avcoat material cracked and chipped off in chunks. We call it “char loss,” but that sounds too clinical. Imagine driving your car at 25,000 mph and having pieces of your windshield fly off. That’s the reality. The debris trail was so significant it risked taking out a parachute.

If that happens with a crew inside? Game over.

NASA has a “Tiger Team” on it, which is shorthand for “smart people in a panic.” They have to solve this physics puzzle without redesigning the entire capsule, and they have to do it yesterday. It feels like trying to fix a plane while flying it.

4. Flying Blind

You launch a test flight to get data. That’s the whole point. So it is baffling to me that we missed so much of it.

It wasn’t just one thing. It was a cascade of failures:

- The Cameras: They didn’t adjust the exposure for the night launch. 32 out of 33 cameras failed to get usable footage. We missed visual confirmation of debris strikes.

- The Hardware: The parachutes sank before we could fish them out of the Pacific. No physical inspection means no certainty.

- The Data: A quarter of the telemetry data is stuck in a format engineers can’t process.

It feels like running a marathon and forgetting to turn on your stopwatch. How do you certify a vehicle for humans when 25% of the flight data is missing or unreadable? You don’t. You dig until you find it, or you fly again.

5. The Expiration Date on the Rocket

Here is the wildest part. The rocket has a shelf life.

The solid rocket boosters—those massive white sticks on the side—are like milk. Once you stack them in the Vehicle Assembly Building, a clock starts ticking. They are certified for 12 months. That’s it.

The launch is targeted for late 2025. If the heat shield fix takes too long, or if the pad repairs drag on, we hit that 12-month wall. Then what? You have to unstack the rocket. Inspect the propellant. Maybe replace the segments.

That’s not a delay of weeks. That’s a delay of years.

It adds a layer of pressure that engineers hate. You aren’t just fighting gravity and physics; you’re fighting the calendar. Every day spent arguing about heat shield data is a day burned off the boosters’ lifespan.

The Bottom Line

Artemis II isn’t just a lap around the Moon. It’s a redemption arc.

NASA is staring down the barrel of corroding parts, missing data, and shattered heat shields. But frankly? I’d rather they find these gremlins now than find them when four astronauts are halfway to lunar orbit. The checklist is long, the stakes are existential, and the clock is ticking.

Can they pull it off? I think so. But it won’t be pretty, and it definitely won’t be cheap.